Car clock, temperature and voltmeter

1.

Introduction

This device was designed to replace the original

digital clock in a Fiat Ducato 1992-1994, mounted just above the inside

rearview mirror. The original clock is not very accurate, only displays time

and is sensitive to interference (e.g. from Xenon headlights). The replacement

device described here does not have these disadvantages, and on top of that

also displays the temperature and the car’s battery voltage. It works on the

car battery and uses the Microchip MCP9800 as a temperature sensor.

This circuit is based around the PIC16F1937 microcontroller.

This chip is actually a small computer contained in a single chip, including

RAM memory, EEPROM, I/O ports, CPU and

so on. When you buy this chip, it comes empty with no program on it. You have

to compile the source code and download the resulting machine code into it, using a PC and a small

programmer attached to the PC and the chip. To get yourself familiar with this

stuff, I suggest you first read this link: Getting started with microcontrollers.

2.

Description

The LCD display used in this design is the Varitronix

VIM-404 (Digikey ordernbr: 153-1047-ND), which is a 0.5” multiplexed 4 digits

7-segment transflective display. It is driven by the PIC16F1937 microcontroller

which has a built-in LCD driver.

The LCD is lit by a LED backlight unit (4.1V): Digikey

ordernbr. 153-1026-ND.

The design is based on Microchip’s

F1 evaluation board. The original PIC16LF1937 was replaced by the

PIC16F1937 to be able to operate at 5 volts (in stead of 3.3 volts) to have a

better contrast on the used LCD display.

3.

Usage

The device is operated with a single pushbutton.

When powered, time is displayed. Press the button to

change the display to temperature, press again to switch to voltage.

Setting the time is done using a unique one-button

user interface:

- First

set the hours. Press and hold the button, the units of the minutes will

increase until reached 0, then the tens of minutes will increase until reached

0, then the hours will increase. Release the button when the hours are correct.

- Then

set the tens of minutes. Press and hold the button, the units of the minutes

will increase until reached 0, then the tens of minutes will increase. Release

the button when the tens of minutes are correct.

- Then

set the units of minutes. Press and hold the button, the units of the minutes

will increase. Release the button when the units of minutes are correct.

4.

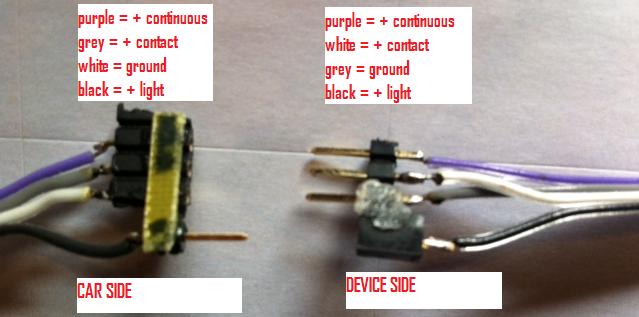

Connection

It is advised to use two 4-pin connector to connect

the device to the car. I made them myself from standard headers:

5.

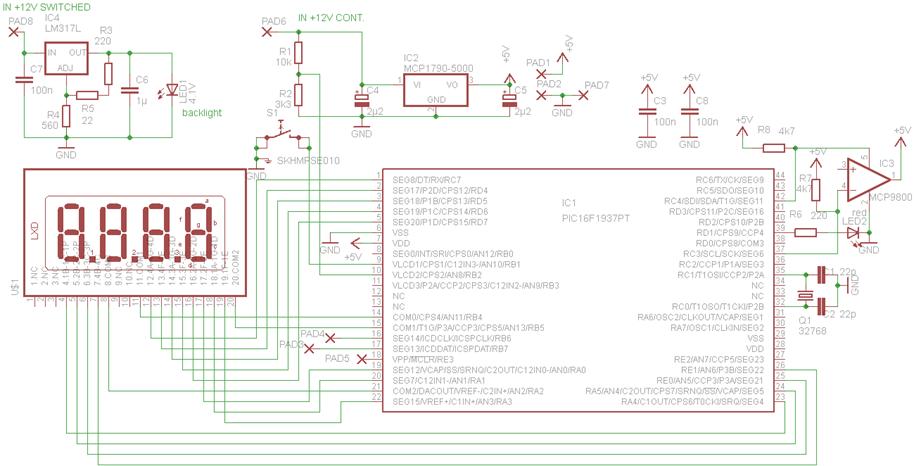

Schematic

diagram

6.

Explanation of the schematic

diagram

(Refer to the schematic diagram).

12V power coming from contact or light switch must be

connected to PAD8. This is for the backlight, it will be on when the engine is

running or when the light is on, by means of IC4 (LM317) which is configured

for 4.1V (R3-R5).

12V continuous power must be connected to PAD6. This

is converted down to 5V by means of IC2, a very efficient power regulator by

Microchip (the MCP1790) which provides the power for the PIC, the LCD and the

temp sensor.

Three common lines and a lot of segment lines are

connected between the LCD display and the PIC’s LCD driver.

The digital temperature sensor is connected to the

clock and data lines of the PIC’s I2C bus.

A common 32768 Hz crystal is connected to the PIC’s

oscillator pins, this is used as the time base for the clock.

R1 and R2 are a voltage divider to measure the battery

voltage. It is connected to an analog input of the PIC.

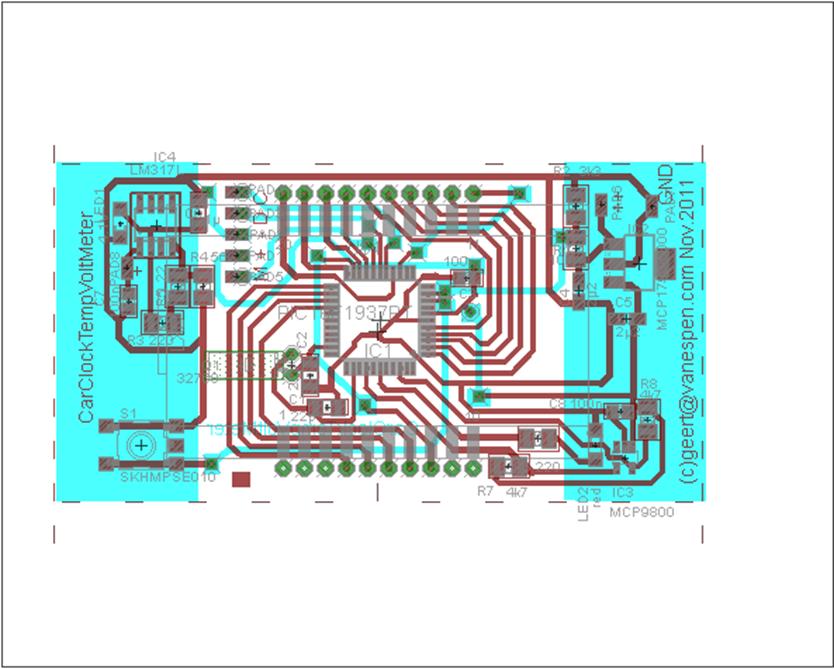

7.

The

printed circuit board

The pcb is designed for smd components.

It is double sided and designed with Eagle (from Cadsoft).

The LCD display, the only non-SMD component, has long

pins and therefore can be mounted on top of the microcontroller, thus saving

space.

The LED backlight unit fits between the LCD display

and the PCB/PIC.

PDF file (top, mirrored) to print on a transparent: Print-layout

PDF file (bottom) to print on a transparent: Print-layout

Link to Eagle file brd file containing the PCB..

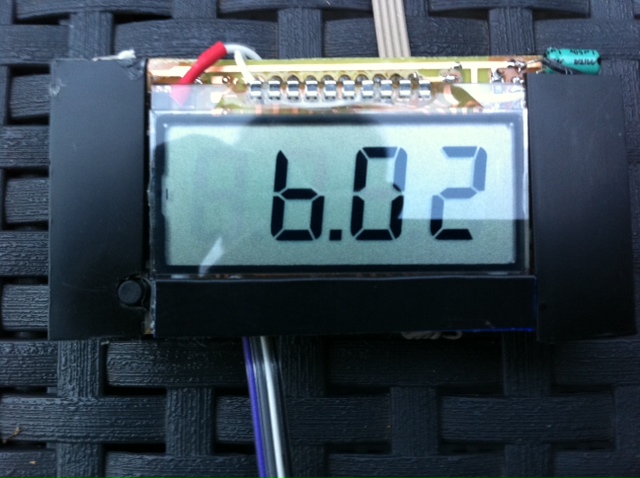

8.

The final device

Below some pictures of the final device.

The original device compared with the new one:

Device showing time, notice the special “font” showing

6 and 9 like in professional displays:

The device built in the mirror console of the Fiat

Ducato:

9.

Tips and tricks

- The

backlight unit can get a little bit warm and this may mislead the temperature

sensor. It is better to mount the sensor off the PCB and connect it with 4

wires.

- In

my motorhome the backlight goes on when either the contact is on or the light

is on. This is achieved with two diodes on both lines from contact and from

light to PAD8.

- Clock

accuracy: the time keeping is done using timer1, operated by a 32768 Hz quartz

crystal. Normally, the timer causes an interrupt every 2 seconds, but since we

set the TMR1 value to about 8000h, this is reduced to once a second. You can

play with the 8000h value: increasing it to e.g. 8001h will make the clock run

a bit faster, decreasing it will make it run slower. You can even use non

integer values, e.g. 8000.5h by incrementing every x interrupts. Using long

observation times for the accuracy, you can get the right value for TMR1,

resulting in a very high accuracy clock.

10.

Programming

The software is written in C (Hi-tech

C supporting Microchip). It uses power saving techniques such as Sleep()

and wake up from sleep after timer1 overflow.

For programming you need the Microchip

MPLAB IDE (free to download) and a PICkit3 compatible programmer. You also

need the Hi-tech C compiler (the lite version, free to download, will do).

Zip file containing all source code, header files and

project files: Link to MPLAB project.

The project file to open is called CarClockTempVoltMeter_5V.mcp, the workspace

file is LCD_CarClockTempVoltMeter_5V.mcw.

Connection to a PIC programmer.

The connector marked “M+-DC” should be connected

(during programming) to the PICkit3 programmer (M corresponds to the white

arrow on the PICkit3).

Home

Home ![]() Back to Electronic

Projects

Back to Electronic

Projects