1.

Introduction

This LED dimmer works with PWM and can be used to dim

LED strips rated at 12V up to 2 amps. The LEDs are driven by a FET transistor.

The dimmer can be configured to operate in several

ways: with a rotary button (potmeter), with one pushbutton or with two

pushbuttons.

The dimmer features soft start in all modes, and soft

stop + dim memory in one or two pushbutton mode.

It also contains a low drop voltage limiter which

limits the voltage on the LED strip to 12V, making it suitable for use in

motorhomes, boats and so on because when charging the batteries the voltage can

rise up to 15V.

I made four versions of the PCB layout: a square

version, a slim-line version, both for PIC18F4550 and PIC18F2550.

This circuit is based around the PIC18F4550 or

PIC18F2550 microcontroller. This chip is actually a small computer contained in

a single chip, including RAM memory,

EEPROM, I/O ports, CPU and so on. When you buy this chip, it comes empty

with no program on it. You have to compile the source code and download the

resulting machine code into it, using a

PC and a small programmer attached to the PC and the chip. To get yourself

familiar with this stuff, I suggest you first read this link: Getting started with microcontrollers.

2.

Description

Using a microcontroller to design a LED PWM dimmer

might look like overkill at first glance. The reason for using a

microcontroller is mainly for implementing things like soft start, soft stop

and dim memory.

The characteristics of the device are:

- 3 operating modes (choosen with dip-switches or

wired connections):

+ pushbutton

operation with 1 pushbutton

+ pushbutton

operation with 2 pushbuttons

+ operation

with potentiometer

- Soft start

- Soft stop (some configurations only)

- Remembers last dim setting (push button operation

only)

- Slide switch for direct access to 100% light

- For use with 12V systems (input 12-16V, output 12V)

- LED strips up to 2A

3.

Usage

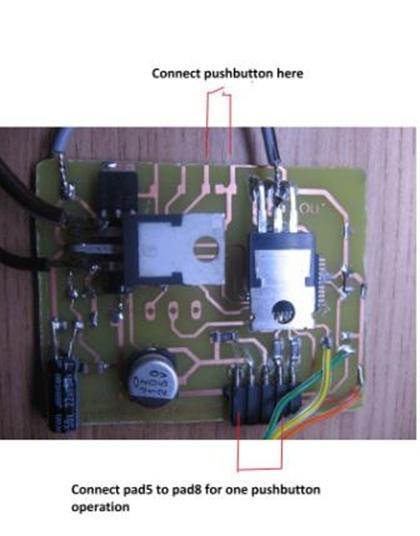

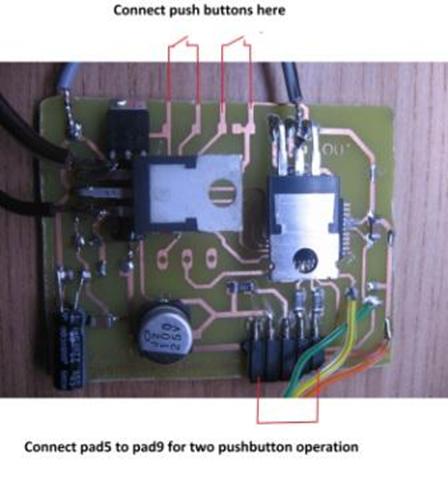

Default operation mode is with a potentiometer. To use

the device with one push button operation, connect PAD8 to PAD5. To use the

device with two push buttons operation, connect PAD9 to PAD5. Pads 5, 8 and 9

can be found on the ICSP connector.

One button operation:

Alternatively mount jumper S3 and set to ON.

To operate:

Press button for a short while to lit the LED. Keep

button pressed to increase light. Release button and hold button again to dim

light. Press button shortly again to set the light off (soft stop). Press

shortly again to put light on again, the light will soft start to last dim

level.

Last dim level is stored in EEPROM at each change of dim

level.

Two button operation:

Alternatively mount jumper S4 and set to ON.

To operate:

Press UP button for a short while to turn the light on

(to last dim level). Keep the UP button pressed to increase the dim level. Keep

the DOWN button pressed to decrease the dim level. Press the DOWN button for a

short while to turn off the light.

Shortcut to 100 percent:

If desired, connect a switch between X and Y or solder

a switch on the PCB. Operating this switch bypasses the current dim level and

directly lights to 100 percent.

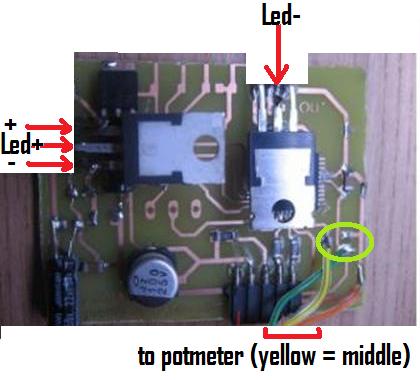

Connect power, LEDs and potmeter:

Solder in/out directly to the power regulator and

mosfet leads (- = 12V ground, + = 12V, Led- and Led+ to LED strip – and +). If

desired, solder a potmeter to green, yellow and orange wires or solder an SMD

potmeter on the PCB:

4.

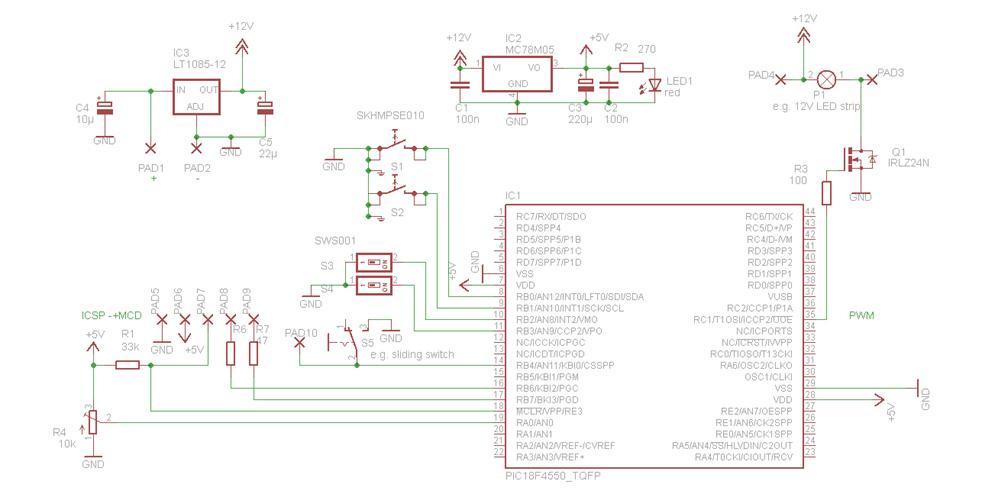

Schematic diagram

To support multiple versions of the PCB (see later)

also multiple versions of the schematic diagram were created. These can all be

found in the Eagle zip file later on.

5.

Explanation of the schematic

diagram

(Refer to the schematic diagram).

The diagram is really simple. A potmeter is connected

to an ADC port (RA0) as a voltage divider. The PIC constantly reads the value

and translates it (using a gamma table) to a PWM value on port RC1. The PWM

output is connected to the gate of MOSFET transistor Q1 which drives the LEDs.

In stead of a potmeter one or two pushbuttons can be

used as a user interface. The PIC constantly reads the buttons and how long

they are pressed (as described above in “Usage”) and translates this to a

suitable PWM value. Every 5 seconds the value of the PWM is stored in EEPROM (unless

it didn’t change) so that the light comes up to the last dim level the next

time it is used.

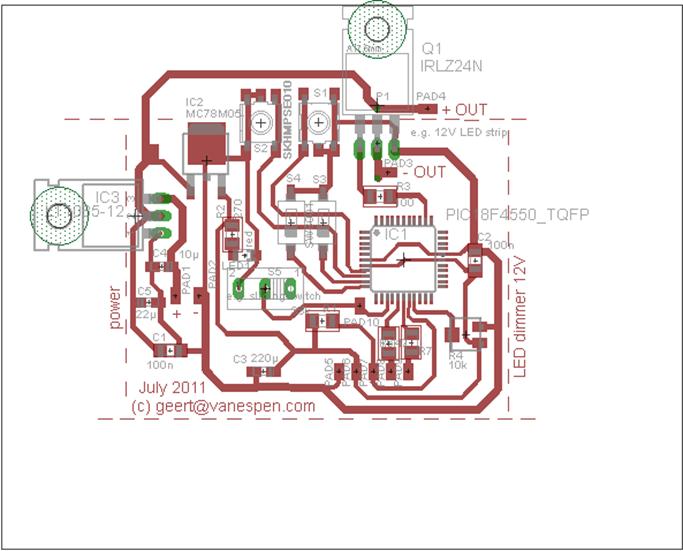

6.

The

printed circuit board

The pcb is designed for smd components.

It is single sided and designed with Eagle (from Cadsoft).

Below is only one version of the PCB. Other versions

can be found in the Eagle zip file later on.

The big transistor (IRLZ24N) and the power regulator

(LT1085-12) are actually not SMD components, therefore 6 holes must be drilled

to fit these. It is best to fit it at the bottom side.

PDF file (mirrored) to print on a transparent: Print-layout

Link to Eagle files zip file containing all versions of the PCB, schematic and pdf files.

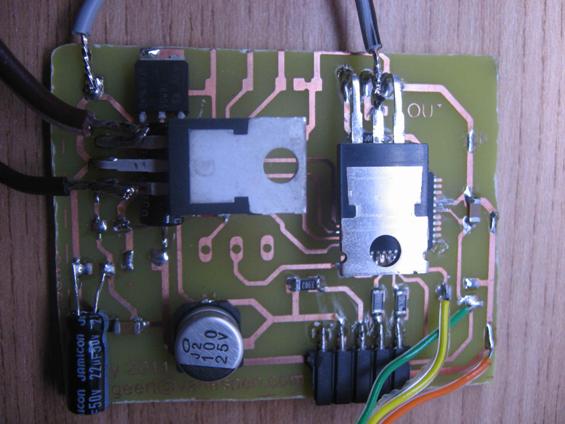

7.

The final device

Below some pictures of different versions of the final

device.

The connector marked “-+MCD” is the in-circuit

programming interface to connect with the programmer (connections: - =, ground

+ = +5V, M = reset, C = clock, D = data).

PIC18F2550 Slimline version (left is the potmeter):

PIC18F4550 square version:

PIC18F4550 Slimline version (PIC not yet mounted):

8.

Programming

The software is written in C (PIC

C18 from Microchip).

It was first prototyped on a Dwengo experimental board

(http://www.dwengo.org).

Since this board uses a PIC18F4550, I designed two projects: one for PIC18F4550

and one for PIC18F2550. The first can, if desired (uncomment #define DWENGO), use

the Dwengo library to show some debug messages on the Dwengo LCD. The

PIC18F2550 version of the project does not need the Dwengo library.

You do not need the Dwengo board and library to build

this project, just the Microchip

MPLAB IDE and a PICkit2 compatible programmer will do.

The software uses the PWM feature of the PIC18Fx550

to dim the light. It uses 64 steps to do so.

Zip file containing all source code, header files and

project files: Link to MPLAB projects

Connection to a PIC programmer.

Pad 5-6-7-8-9 must be (temporary) wired to a PIC

programmer (5=-, 6=+, 7=VPP, 8=clock, 9=data), e.g. a PICkIt2 compatible

programmer.

Gamma-table:

The software uses a gamma table (g[] in the source

code) to translate percentage to a correct duty cycle for the light that

visually corresponds to that percentage. This table is suitable for LEDs, I

don't know what it will look like on classical light bulbs. It might be needed

to change the table in this case.

Home

Home ![]() Back to Electronic

Projects

Back to Electronic

Projects